CRISPY MASTER is a frying oil degradation prevention device

Advantages of CRISPY MASTER®

frying oil consumption

CRISPY MASTER® generates a high potential with a particular frequency from the electrode plate.

Then, convection by electrons that efficiently transmits heat is generated.

Thus, required set temperature can be lowered and oil degradation caused by heat will be eventually prevented as the heat conduction will be improved. It is said that if the set temperature is lowered by 10°C, the oil oxidation speed will be halved.

*We suggest to lower the set temperature by 5℃ to 10℃

transmission of heat

significantly mitigated!

Oil odor is also caused by oxidation of oil. As CRISPY MASTER® significantly suppresses the oxidation of oil, annoying odors on clothes and hair are also greatly reduced.

Working principle

Oil molecules do not release negative electrons.

So, it prevents oxidization.

In the chemistry, the loss of negative electrons is called oxidation. Oxidation of cooking oil also proceeds by losing electrons, but CRISPY MASTER® prevents electrons from jumping out of cooking oil molecules in a fryer by emitting large number of electrons from the electrode plate (If you compare it to an “electron bath”). Therefore, the cooking oil will be less likely to combine with other ingredients and you can keep the original flavor of cooking oil.

Even if the oil turns black, the product will be fried beautifully.

When molecular bonds occur, carbon (carbonized state of batter, fried powder, ingredients, etc.) adheres to the product, turning it black. CRISPY MASTER® generates a negative high potential in the oil tank to dissolve molecular bonds, making it difficult for carbon molecules to stick to the product.

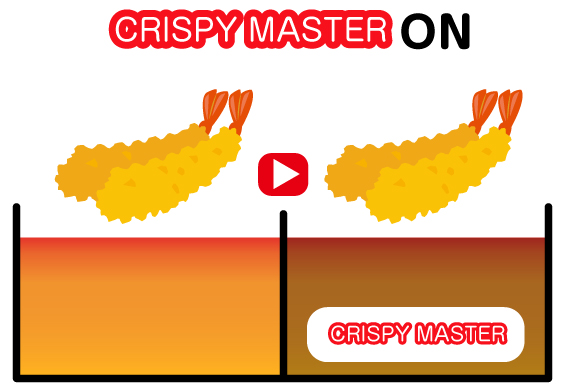

The batter is crispy and the inside is fluffy.

CRISPY MASTER® generates a high potential with a particular frequency from the electrode plate. As electron convection occurs and heat is effectively transferred to the ingredients, so the moisture in the batter quickly evaporates, making the batter crispy.

Customer feedback

As a result, we succeeded to reduce the consumption of frying oil for two 350-liter continuous automatic fryers to less than half thus it leads to a significant cost reduction. We are currently using a digital measuring instrument to measure the deterioration of oil, and the deterioration value is kept low by using the frying oil oxidation prevention device “CRISPY MASTER®” even if the oil is continuously used for a long time. All the staff are happy that the working environment has been improved as oily smoke and oily smell in the factory has drastically decreased.

In addition, I like it because oil drains off products better and the crispness lasts longer.

Hats off to the excellent quality of “CRISPY MASTER®”.

restaurant chain

The models compatible with capacity of 10-3000 liters fryer are available in CRISPY MASTER® series

We have proven record of over 10,000 units for individual shop fryers

as well as large-scale continuous fryers for food factory

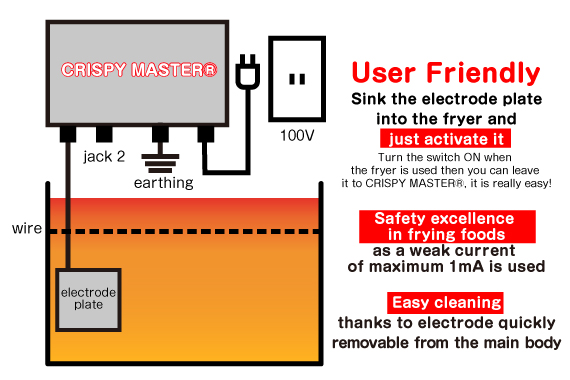

Installation and Safety

Place CRISPY MASTER® with a dedicated stand or fix it to the wall in a place where it does not get in the way.

Take the power supply (100V or 200V).

“Electricity bill is about 5 to 10 yen a month. (in Japan)

CRISPY MASTER® consumes less power, so the running cost is low.

Insert the plug of the cable extended from the electrode plate into the white jack at the bottom of the main unit.

Place the electrode plate in the oil as shown in the illustration.

Turn on CRISPY MASTER’s switch and you’re done.

Contact

* If you request a demonstration, please fulfill a Survey Sheet.

Representative: Minoru Tanaka, President & CEO

tanaka@comcom-eco.co.jp